+86 755 23057280

English

+86 755 23057280

English

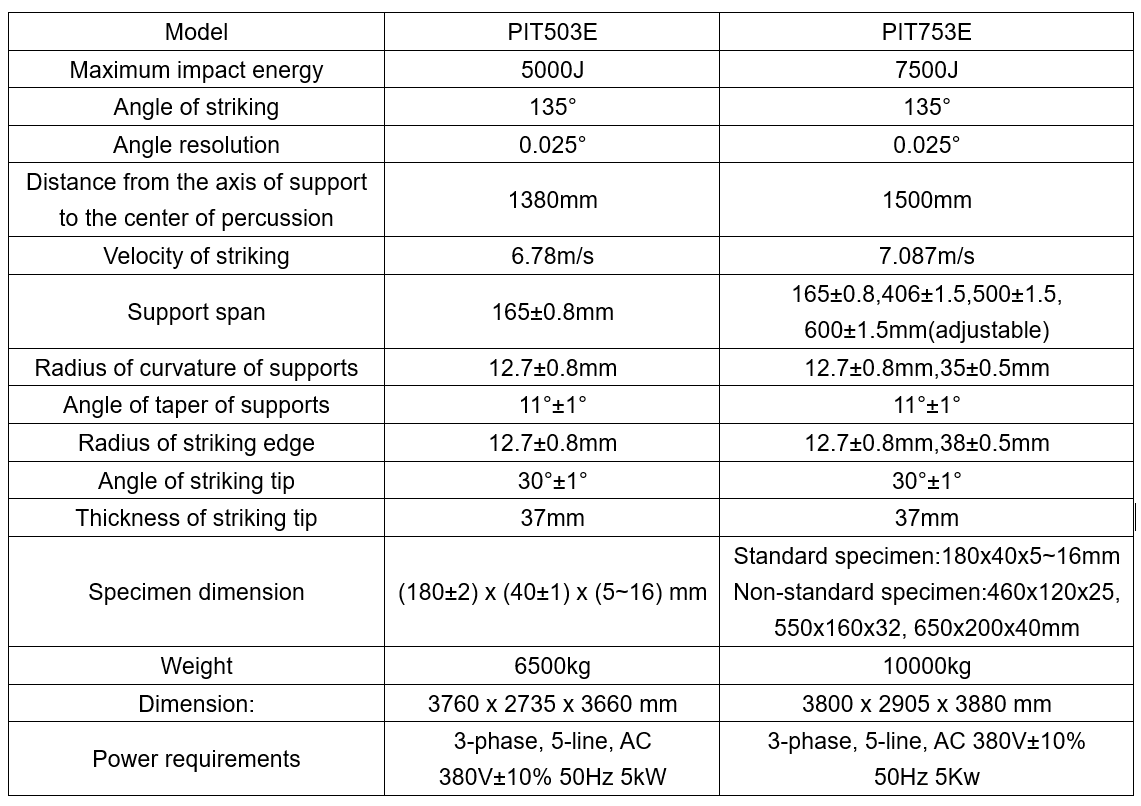

Model: PIT503, PIT753

Type: Type E

Maximum impact energy: 5000J, 7500J

Standards:

ASTM E604, GB/T 5482

Functions:

This type of testing machine is specially used for dynamic tear testing (DT test) of metallic materials.

Features:

1. Automatic control: specimen feeding, impacting, pendulum raising and specimen collecting can be fully automatically operated.

2. Heavy duty seat and frame ensures stiffness and accuracy, reducing shock after impact. Seat is made of high strength carbon steel, frame is made of H shape 300# steel. Specimen anvil is made of 45# forged steel with quenching and tempering treatment, ensuring high strength and stability.

3. High strength pendulum body ensures stiffness in axial and transverse direction. Pendulum consists of pendulum body, arm, hook and striking knife. Arm is made of 45# steel and then machined to H shape. Body and arm is treated with quenching and tempering. Striker knife is made of tool steel with hardening treatment and hardness can reach 62HRC.

4. Three types of pendulum raising device provides three types of impact energy without changing pendulum.

5. Driving system

Use motor to raise pendulum with constant torque output and precise raise. Cycloidal-pin gear speed reducer directly drives clutch with more advantages of simple structure, high speed-reduction ratio, high overload resistance, high efficiency, and small size and easy to maintain.

6. Brake system

Equipped with pneumatic braking device avoids clutch working at high speed, reduces clutch impact abrasion, and extend its life. Brake system includes brake discs, pads, levers and pneumatic cylinder. It is used to reduce speed and stop the pendulum when raise to top, then clutch closes and drives the pendulum to initial striking position.

7. Equipped with specimen feeding and positioning device provides rapid feeding, precise positioning, high efficiency and safety, and reducing labor intensity.

After placing specimen onto specimen platform, gripping cylinder starts to work and position the specimen in length direction; then moving cylinder carries specimen in front of specimen support; finally feeding cylinder carries specimen onto specimen support, and all cylinder returns to initial position.

8. Equipped with multiple energy display device showing test results at the same time.

9. Equipped with specimen collecting device, bring the tested specimen out of the machine. It allows operator to collect specimen without going inside, greatly improving efficiency and working safety.

10. Specimen support consists support and anvil. Anvil is made of CrMn steel with hardening treatment, reaching 58~62HRC hardness.

11. Full-closed safety shield prevents splitting of cracked specimen. Limit switch on the door ensures operator’s safety.

12. Apply German Siemens S7-200 series PLC as controller. Full-automatic operation reduces labor intensity, and improves working efficiency and safety.

Parameters:

Nucor steel in USA

Dear customers, please send your comments and suggestions to us via the following form. We will contact you as soon as possible.

Scan and follow us

Copyright @Shenzhen Wance Testing Machine Co., Ltd.

All Rights Reserved Design by:zuoan.com.cn