+86 755 23057280

English

Functions

This type of machine is especially designed for drop-weight test of pipe and plate (including plastics, ceramic, Nylon, and building materials). Equipped with force transducer, precise data sampling and measurement system, it fully satisfies instrumented impact tests complying with international standards.

Standards

ASTM D 7136/D 7136M, ASTM D 7192, ASTM D5628

ASTM D 3763, ASTM E 23, ASTM D2444, ASTM E208

ISO6603, ISO 148, ISO 14556, EN 10045, DIN 50115

Significance and use

Compared with traditional pendulum impact testing machine, instrumented type is more useful for accurate analysis of material property during crack, facilitating the engineers to understand the most fragile part of materials when developing new materials.

In addition to providing an measure of total absorbed energy (Wt), instrumented testing enables the determination of characteristic force, energy, and displacement parameters, such as the pre-maximum force energy (Wm); the post maximum force energy; the general yield force (Fgy); the force at brittle fracture initiation (Fbf); the arrest force (Fa).

Wance is the leading R&D and manufacturing of instrumented impact testing system in China, and has experienced experts for force transducer design. Combined with our high speed data sampling system, Wance provides the full complement of solutions for laboratory, ranging from 0.1J for engineering plastic to 100,000J for steel DWTT test.

Features

1. Motorized control by computer: setup of drop height and striker mass, automatic lift and release of striker, automatic data acquisition

2. Automatic control: anti-rebound to prevent secondary impact, potion the zero point for different specimen, clamp the striker to preset height, and detect the door open/close. Dedicated control panel and touch screen can satisfy test requirements, real-time display of crosshead height, set up of drop height, mass and other parameters. Optical sensor is to detect impact speed before/after impact.

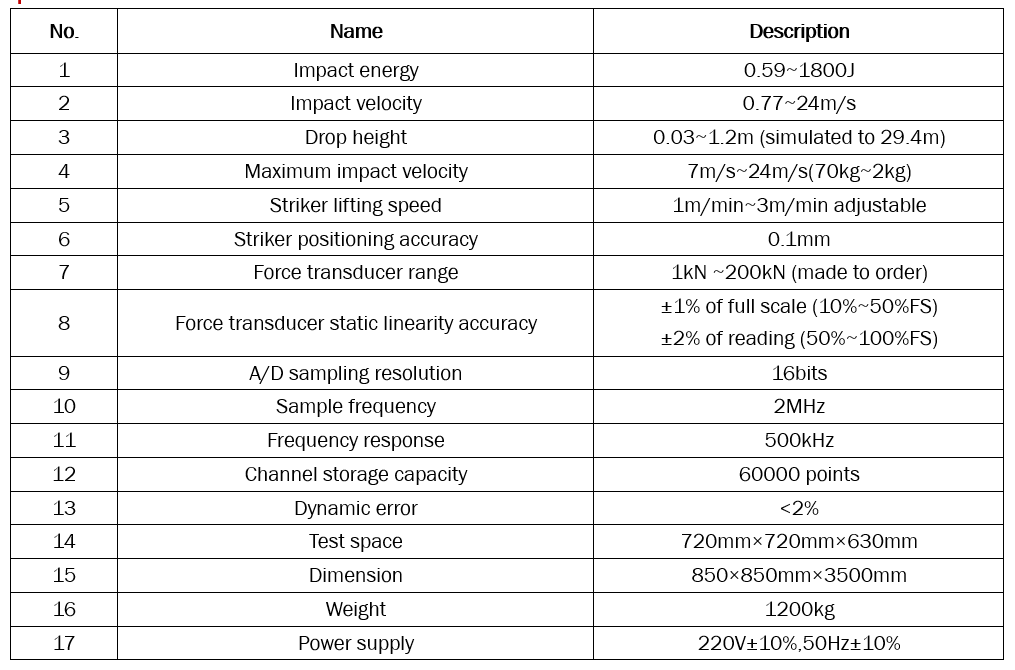

3. High speed instrumented test system offers high precision transducer, allowing to automatically sampling data and plot force-displacement curve for analysis. Sampling frequency is up to 2MHz, with 6000 points storage capacity on each channel, and dynamic loading measurement error is less than <2%.

4. Pneumatic fixture for plastic plate test

5. High precision and high speed lifting system provides with power-off protection function, preventing accident drop if power off

6. Clamp/release mechanism features high safety to avoid accidence, such as power off. Equipped detect and alarm devices prevents loosen clamp

7. Full-closed protection shield protects operator from splitting specimen. Interlock door further ensures safety

8. Optional high/low temperature chamber is designed with automatic close function to avoid temperature fluctuation

9. High/low temperature chamber is designed with anti-fog observation window

Main frame

Main frame consists of seat, top plate, guidance columns and support columns. Seat is made of 45# steel plate and 4 support rods. The seat can accommodate different fixtures for different specimens test.

Support columns are steel pipe to guarantee the whole main stiffness.

The connection among support columns, top plate and seat is flange with high stability.

Guidance columns are precise smooth columns with chrome plated. Upper and lower ends are connected with screw to ensure high stiffness.

Striker lift mechanism

It consists of servo motor, speed reducer, convoy belt, lead screw, and crosshead. Panasonic servo motor provides control with high accuracy to 1mm.

Clamp/release mechanism

Self-lock function is specially design to ensure exceptional safety.

Striker assembly

Striker assembly consists of guide sleeve, striker, force transducer and tup. It is flexible to change striker, transducer and tup.

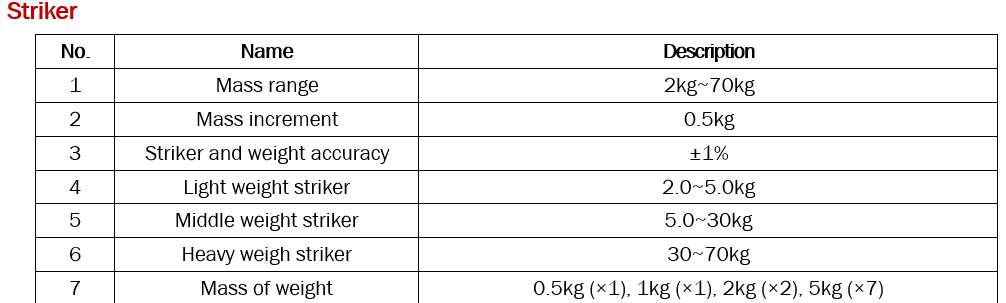

1) Striker: by adding masses, light weight striker can meet 2kg~5kg, medium weight can meet 5kg~30kg, and heavy weight striker can meet 30kg~70kg.

2) Force transducer: various capacity transduces are available from WANCE, from 11J~100000J.

3) Tup: customized and designed according to different test standards

Test fixtures

1) Charpy impact fixture

Comply with ISO 148, EN 10045, GB/T 19748, GB/T 229, JJG 145, GB∕T 3808

2) NDT impact fixture

Comply with ISO14556, GB/T 19748-2005

3) Composite impact fixture

Comply with ASTM D7136

Spring driven device

This mechanism provides high speed impact on specimen, depending on high strength spring beside of free drop.

Speed detector

Speed is measured by optical encoder. By measurement of speed at the instant before impact and after impact, the calculated kinetic energy difference before and after impact is the absorbed energy and friction losses. By correction of friction losses, the exact absorbed energy can be calculated.

Anti-rebound device

This device is to prevent secondary impact on specimen when tup rebounds after impact. It consists of link mechanism, pneumatic cylinder, cushion block and pad

Safety protection shield

Fully closed protection shield prevents broken specimen from splitting. Interlock door further improves safety.

Control electronics

SIMENS programmable PLC is used for automatic control, including striker clamp, lift, zero positioning and impact. Touch screen is used for test interface. Rotary encoder is used for measurement of height.

Instrumented system

1) Principal

Force transducer in striker transfers the force signal to high speed data conditioner for amplification. Then the signal is A/D converted by high speed sampling card, and transferred to computer for storage and analysis.

2) Features

• Force transducer: Bridge strain gauge type force transducer with various energy is available, ranging 0.1J to 100,000J in energy and 1,000N~1,000,000N in force. It provides high frequency, high linearity and durability.

• High speed data sampling card made from American NI: 16bits A/D resolution and 1.25MHz high speed data sampling permit reproduction of instantaneous force changing with good fidelity. Industrial standard PCI interface is easy to communicate with computer.

• High speed signal conditioner: Enlarge the strain signal to match the analog signal input range required by high speed data sampling card, improving measurement resolution and sensibility. 500kHz band width ensures high frequency signal without attenuation.

Instrument data analysis system - Software

· Automatic curve fitting of force vs. displacements

· Automatically determine Fgy, Fm, Fiu, Fa, and other characteristic parameter, further determine after calculation Sgy, Sm, Siu, Sa, St, Wm, Wiu, Wa, Wt and others.

· Fully automatic data processing permits to get test results and report after each test immediately.

· Curve and raw data can be exported

Shanghai Nuclear (China)

Dear customers, please send your comments and suggestions to us via the following form. We will contact you as soon as possible.