+86 755 23057280

English

Application and properties of diamond composite sheet

Diamond compact (PDC) as a new type of composite material, although only decades development history, but because of its high hardness, good wear resistance characteristics, are widely used in oil drilling, drilling bit on geological exploration, coal and nonferrous metals and alloys, tungsten carbide, graphite, plastic, rubber, ceramics and wood materials such as cutting, etc. In recent years, due to the more and more extensive use of diamond composite sheets, the performance requirements are gradually improved, and the corresponding performance detection methods have also gone through a rapid development process, and become mature in terms of the accuracy and effectiveness of detection.

1. What is diamond composite sheet

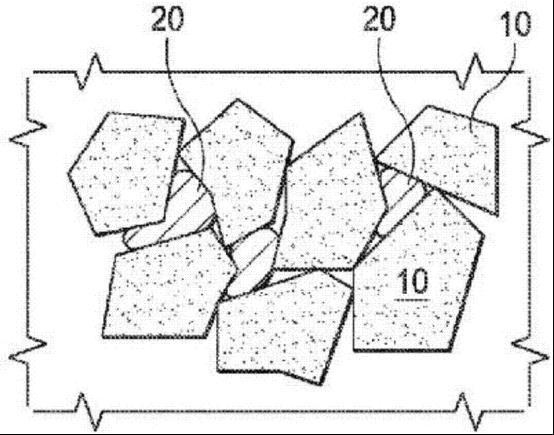

Diamond composite sheet (PDC) is a composite material sintered by diamond micro powder and hard alloy substrate under ultra-high pressure and high temperature. Therefore, it not only has high hardness, high wear resistance and thermal conductivity of diamond, but also has the strength and impact toughness of hard alloy. The surface layer of diamond composite sheet is polycrystalline diamond sintered from powder of different diamond size, which has very high hardness, wear resistance and long working life. The bottom layer is generally tungsten-Cobalt type hard alloy, which has good toughness. It not only provides good support for the surface layer of polycrystalline diamond, but also makes it easier to be brazed to various tools, making it an ideal material for manufacturing cutting tools, drilling bits and other wear-resisting tools.

2. Classification and application of diamond composite films

According to the different application scope, the diamond composite film products

on the market are mainly divided into the following two types:

1. Drilling and mining diamond-like composite sheets

Properties of diamond composite sheets

The diamond composite sheet is widely used because of its superior material properties. First of all, diamond composites have high hardness and wear resistance (attrition ratio)., according to the determination of the hardness up to about 10000 HV, PDC is the synthetic materials in the world's highest hardness, higher than the hardness of engineering ceramics and cemented carbide, due to the high hardness, and isotropic, the diamond compact has good wear resistance, which makes the material is widely used as a drilling and cutting tools.

Secondly, diamond composite film has strong thermal stability. Thermal stability refers to the chemical stability (degree of diamond inking) of the polycrystalline layer after being heated to a certain temperature in atmospheric environment (in the presence of oxygen), the change of macroscopic mechanical properties and the influence on the firmness of the interface bond of the composite layer after cooling. The thermal stability of the diamond composite sheet determines its range of use. The thermal stability of the composite sheet is the heat resistance, and it is one of the important performance indexes to measure the QUALITY of PDC, as well as its strength and wear ratio.

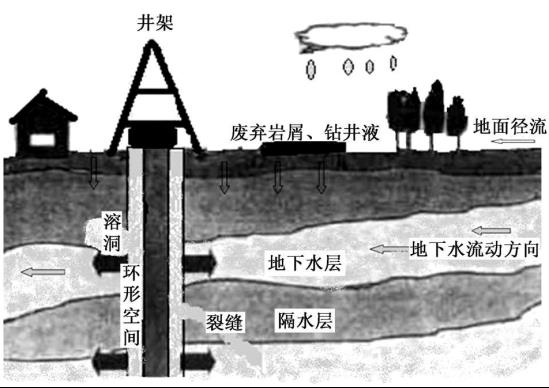

In addition to hardness, wear resistance and thermal stability, impact toughness is also a very important performance index of diamond composite sheets. As cutting tools, diamond compact was widely used in the oil and gas drilling, but in the process of drilling, due to the joint action of axial force and the level of the cutting force, tool and pore wall friction, drill column bending, uneven and residual rock powder at the bottom of the bore, rig vibration, the influence of such factors as tend to drill on the diamond compact caused great impact. Therefore, the impact resistance not only reflects the toughness and bond strength of the composite sheet, but also is a key comprehensive index affecting the use effect and life of the composite sheet. With the progress of the test technology, the detection method for the impact resistance performance has been constantly improved.

WANCE DIT122Z-1 Diamond drop weight impact testing machine is equipped with automatic control system, which realizes the automatic process of hammer lifting, impact and grabbing, greatly reducing the labor intensity of operators, improving work efficiency and operation safety. The automatic control system is designed with Siemens PLC programmable controller and equipped with touch screen as the terminal operator. Due to the high reliability and stability of PLC and strong anti-interference ability, the reliability and stability of the whole control system are also very high, and there will be no wrong action, which greatly improves the safety of the test personnel. In addition, convenient replaceable hammer body is suitable for different types of sample requirements, equipped with high precision and accurate positioning device to achieve accurate impact.