+86 755 23057280

English

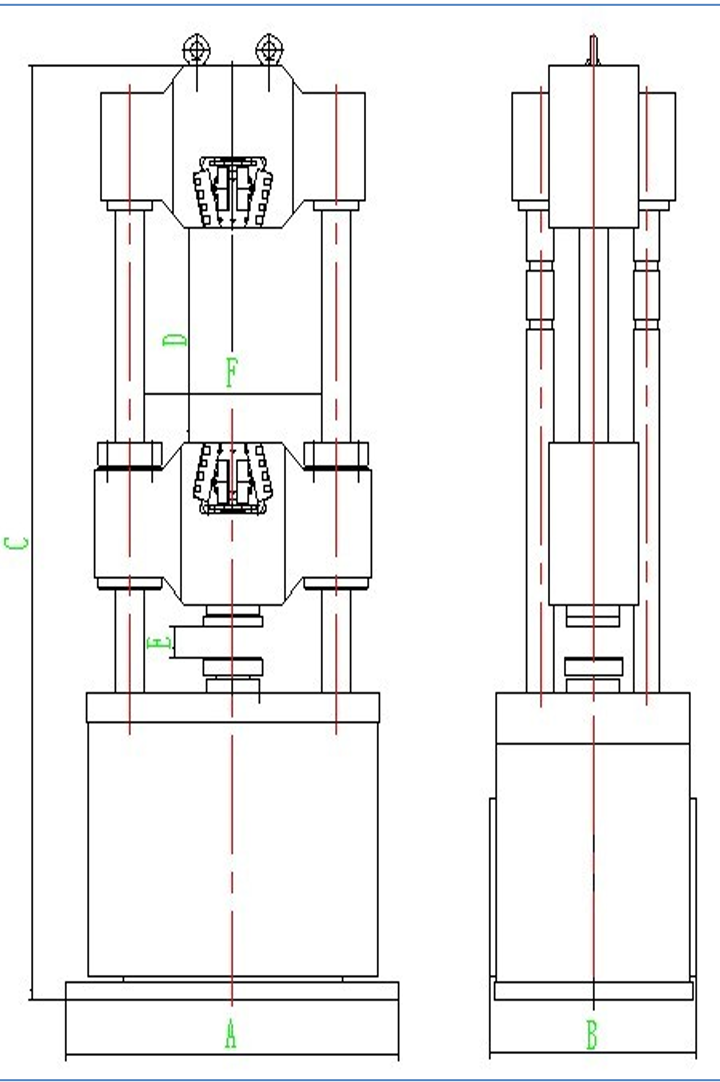

Load Frame Configuration: 4 or 6 column, servo-controlled hydraulic

Capacity: 200kN, 300kN, 500kN, 600kN, 1000kN, 2000kN

Test Space: Dual zone (tension on top, compression on bottom)

Typical specimens: Fasteners, rebar, chain, welds, castings

Frame

1. Lead screw driven crosshead to adjust the test space

2. High-Stiffness 6-column load frame design incorporates 3-position crosshead, adjustable specimen positioning, precision guide columns, thick crosshead and base beam minimizes load frame stored energy while producing reliable, stable, accurate load, strain and modulus values.

3. Ergonomically designed load frames ensure safety, reduce operator fatigue, and provide the highest level of flexibility.

4. Standard Dual Zone Test Space for reducing setup time

5. "Quick Return" hydraulic valve for higher throughput

6. Automatic limit checking for crosshead position, overload, over temperature, over voltage, etc.

7. The system can return automatically, the oil cylinder can return the original position via manual or automatically after finishing testing

8. Positive specimen holding is ensured by the wedge action of hydraulic operated grips

9. Imported encoder mounted on the seat is for position measurement of crosshead with high accuracy

10. Imported servo valve provides high stability and reliability

Hydraulic power unit

The main cylinder of the machine and the fixture share the same hydraulic power unit, which is equipped with the plug-in logic valve provided by American SUN company,

which can intelligentlyadjust the system pressure. Pressure follow-up technology can ensure that the system pressure is always only 2MPa higher than the required pressure of the cylinder, when the test force is low, the output pressure of the oil pump is also low, and when the test force is increased, the output pressure of the oil pump is also increased at an equal speed. The differential servo pressure is adjustable to ensure that the system does not produce tremors when completing different tests, thus saving energy and reducing heat.

1) Low noise: The screw pump provided by SETTIMA company in Italy, combined with the seller's unique oil source production technology, greatly reduces the noise of the whole machine and improves the working environment of the test personnel.

SETTIMA screw pump has the following characteristics, as shown in Figure 3-3:

· Stable pressure without pulse, rated output pressure can reach 27.5MPa.

· The design structure eliminates the phenomenon of trapped oil, can carry higher pressure and flow, and has higher efficiency.

· The rotor has a gentle meshing surface, which reduces noise and is very quiet.

· High volumetric efficiency, good low-speed performance, strong medium adaptability and effective energy saving.

· The component has high wear resistance, long service life, simple structure and easy maintenance.

2) The MOOG servo valve is used to ensure the control accuracy. The servo valve is shown in Figure 3-4. Servo valves have the following advantages:

· Driven directly by a high driving force permanent magnet linear motor.

· Dynamic performance is not affected by pressure, stable control.

· Low hysteresis and high resolution: fast response and high control accuracy.

· Low power consumption at and near hydraulic zero.

· Standardized spool position detection signal, through which the system operation can be obtained, and the valve maintenance is very beneficial.

3) Easy installation and maintenance. The hydraulic unit adopts independent semi-open structure. The front and side of the cover are open-door structures, and the backplane can be easily disassembled for easy maintenance and component replacement.

4) Small heat, good heat dissipation effect. The unique differential pressure servo control technology significantly reduces the system heat output. Hydraulic unit adopts semi-open structure with air cooling cooling device. The cooling device can be started automatically or manually. When the temperature reaches the set temperature of the oil temperature gauge switch, the air cooler motor automatically starts, so that the system can continue to work normally under high temperature environment.

5) High filtration accuracy: the filter element of the high pressure filter is made of glass fiber filter material, which has the advantages of high filtration accuracy, large oil flow capacity, small original pressure loss, large amount of pollution, etc. Its filtration accuracy is calibrated by absolute filtration accuracy. Multiple filtration, filtration accuracy of 5μm, reduce the failure rate, improve the service life of the servo valve and oil pump.

6) Pressure overload protection function: When the pressure exceeds the rated pressure of the system, the relief valve overflows to ensure the safety of the entire system.

7) Sealing method: The hydraulic pipeline from the oil pipe to the joint are imported products, the pipeline uses high pressure hose sleeve cone sealing joint, the sealing effect is very good, and can be disassembled many times.

Controller

WANCE DTC-500 digital controller offers high speed and closed loop control of load, displacement and extension.

· Four-layer PCB layout, anti-resistance, high reliability;

· Connector with locking function, strong and durable, not easy to fall off, the interface layout is neat and reasonable, easy to plug and unplug;

· 6-channel 24 bit AD measurement channel;

· Up to 1200Hz sampling frequency;

· Up to 1200Hz closed loop control frequency;

· 20 bit resolution digital input;

· 3-channel high-speed digital acquisition, which is used to collect orthogonal pulse signals such as photoelectric encoder and grating ruler, with the highest signal acquisition frequency up to 4MHZ;

· Ethernet/USB interface mode is supported, and the transmission rate is greatly increased to support higher sampling frequency. Ethernet interface adopts special high-performance Ethernet interface chip and hardware logic gate circuit to realize complex TCP/IP protocol cluster, which has significant advantages such as high reliability and good security;

· TEDS function: transducer self-identification system, interface features can be set online by software, system structure is more reasonable;

· It has three closed-loop (force, extension and displacement) control functions, realizing all-digital three closed-loop control of force, extension and displacement. Each control loop can automatically switch between different control rings, and realize smooth transition when switching between different modes;

· Perfect limit protection, overload protection, emergency stop and other safety protection functions.

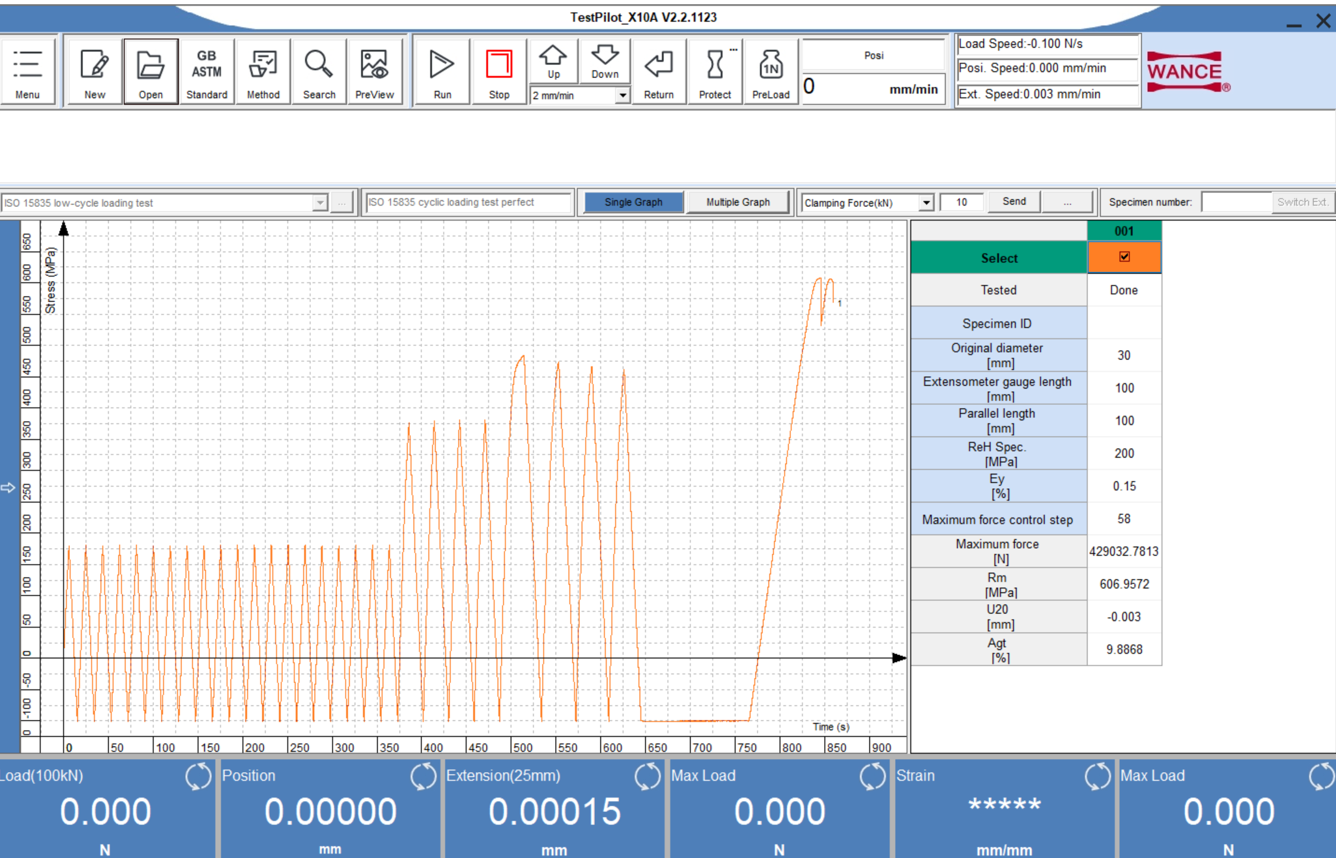

Test software

TestPilot is designed to enhance your ability to perform accurate and repeatable mechanical testing of materials, components and finished goods across a full spectrum of applications. It provides the simplicity and ease-of-operation needed for quick and efficient quality assurance and quality control testing, the flexibility to adapt readily to changing requirements, and the sophistication to address unique or complex demands. The software’s intuitive operator interface, powerful analysis and reporting, and growing host of test methods make it an excellent foundation for establishing and sustaining a truly global standardized testing methodology.

TestPilot software is fully compatible with all WANCE electromechanical universal testing machine ETM Series. This software features a large, growing host of pre-packaged test methods to help you quickly and efficiently meet the requirements of global test standards such as ASTM, ISO, DIN, EN, BS, and more. Selected by an operator at runtime, these methods are crafted to meet the specific test flow, analysis and reporting requirements of industry standards across a range of specimen and test types. Pre-packaged test methods are available in a wide selection of bundled sets, including: Polymers & Plastics, Metals, Construction Materials, Biomedical Products, paper Products, adhesives, foam, textiles and more.

Features

• Versatile, easy-to-use TestPilot software with a large and growing library of standards-compliant test methods (ASTM, ISO, DIN, EN, BS, and more)

• Modular design permits easy upgrading

• Multiple graphs on the same screen & report to observe multiple events at the same time: real time display curves, like displacement-load, stress-strain, displacement-time, load-times, and others.

• Powerful analysis function can calculate typical value and display on the curve, like Fm, ReL, ReH, Rp.

• Measurement unit: Users can select SI, or others, like N, kN, Kgf, lbf, Mpa, and so on, user can define the unit by themselves using formula.

• Customizable report format with full flexibility of adding & removing items in terms of layout, content, graphing to suite the exact test requirement, like company information, statistics, and etc. Test report can export to Excel or Word.

User Authorization Management

User authorization management is easily to define software access for different level of operators, like lab manager, operator and others.

Test Standard Library

Pre-packaged test standards are available in a wide selection of bundled sets, including: Polymers & Plastics, Metals, Construction Materials, Biomedical Products, paper Products, adhesives, foam, textiles and more.

· End user is able to add/edit the predefined standards.

· Calculation formula can be defined by end user freely.

· Import / export standards from the same version software.

Test Methods

Very intuitive design to define a test procedure

Run the test

Select one test project and click “Run”.

Real-time display of test data and graph: maximum 3 curves can be displayed in one window.

Test curve analysis

This software facilitates the flexible display, handling and sharing of test data to meet a full range of industry-standard analysis and reporting requirements.

It features post-test analysis with easy-to-understand displays and highly flexible, interactive data plots. Features include movable markers, text, and construction lines, and the ability to define a region of interest and easily zoom in for closer inspection. The review screen also allows post-test data to be displayed across multiple graphs, simultaneously.

Test report

Test results can be output to standard, presentation-quality reports and plots, or a format customized to meet your particular data sharing needs. It is easy to export to Excel and Word.

Measurement unit setup

User can select SI and other measurement unit according to test requirements.

The unit can also be customized by use for specific use.

Separate Installation Center software for hardware setup

DTC500 Installation center software is for hardware configuration, like load cell and extensometer calibration, add new load cell and extensometers.

Frame dimensions

Model | Outside dimension A×B×C (mm) | Tensile space D (mm) | Compression space E (mm) | Test width F (mm) | Piston travel (mm) |

HUT305A | 820×570×1955 | 520 | 520 | 410 | 150 |

HUT605A | 940×650×2400 | 710 | 700 | 435 | 250 |

HUT106A | 1020×670×2600 | 750 | 660 | 450 | 250 |

HUT206A | 1370×820×3300 | 900 | 750 | 730 | 250 |

HUT306A | 1320×950×3958 | 1200 | 1000 | 530 | 300 |

Model | HUT305 | HUT605 | HUT106 | HUT206 | HUT306 | ||

Type | Type A | ||||||

Capacity (kN) | 300 | 600 | 1000 | 2000 | 3000 | ||

Calibration accuracy | Class 0.5 | ||||||

Force accuracy | Better than ±0.5% | ||||||

Force range | 1% ~ 100%FS | ||||||

Resolution | 1/500000FS | ||||||

Extension range | 1% ~ 100%FS | ||||||

Extension accuracy | Better than ±0.5% | ||||||

Extension resolution | 1/500000 of max extension | ||||||

Position resolution | 0.004mm | ||||||

Position accuracy | Better than ±0.5% of reading | ||||||

Actuator (piston) stroke (mm) | 150 | 250 | 250 | 250 | 300 | ||

Actuator (piston) speed (mm/min) | 0 ~ 180 | 0 ~ 140 | 0 ~ 90 | 0 ~ 70 | 0~100 | ||

Middle crosshead speed (mm/min) Only for test space adjustment | 350 | 270 | 310 | 360 | 240 | ||

Force loading speed | 0.05% ~ 2% FS /s | ||||||

Column number | 4 | 6 | 6 | 6 | 6 | ||

Column spacing (test space width) (mm) | 410 | 435 | 450 | 730 | 530 | ||

Maximum tension space (mm) | 520 | 710 | 750 | 900 | 1200 | ||

Maximum compression space (mm) | 520 | 700 | 660 | 750 | 1000 | ||

Diameter of round specimens (mm) | Φ10 ~ Φ20 Φ20 ~ Φ32 | Φ10 ~ Φ21 Φ21 ~ Φ31 Φ31 ~ Φ40 | Φ12 ~ Φ23 Φ23 ~ Φ35 Φ35 ~ Φ45 Φ45 ~ Φ55 | Φ15 ~ Φ30 Φ30 ~ Φ55 Φ55 ~ Φ70 | Φ30~Φ70 Φ70~Φ110 | ||

Thickness of flat specimens (mm) | 2 ~ 13 13 ~ 25 | 2 ~ 16 16 ~ 30 | 2 ~ 20 20 ~ 40 | 10 ~ 40 40 ~ 70 | 10~60 60~100mm | ||

Compression platens (mm) | Φ120 | Φ150 | 200x200 | Φ240 | Φ280 | ||

Frame dimension (length × width × height) (mm) | 820x570x1955 | 940x650x2400 | 1020x670x2600 | 1370×820×3150 | 1320×950×3958 | ||

Hydraulic Power Unit dimension (length × width × height) (mm) | 1150×600×900 | 1150×630×1000 | |||||

Hydraulic Power Unit weight (kg) | 300 | 400 | |||||

HPU flow rate ( L/min) | 5 | 5 | 5 | 7.2 | 12 | ||

Power consumption (kW) | 2.5 | 3.5 | 4 | 6 | 6 | ||

Power supply | 3-phase, 5-line, AC380V, 50Hz | ||||||

Frame weight (kg) | 1500 | 2500 | 3500 | 6800 | 10220 | ||

Almost all Bangladash steel companies bought this type of machine for laboratories.

Mohammadi Steel Works Ltd.

Rahim Steel Mills Co. (PVT) Ltd.

SALAM Steel Re-rolling Mills

Magnum Steel Industries Limited

Anwar Group

Rani Re-rolling Mills Ltd

Moh Steel

.

.

Mohammodi Steel

Rahim Steel

Rani Steel

Dear customers, please send your comments and suggestions to us via the following form. We will contact you as soon as possible.