+86 755 23057280

English

+86 755 23057280

English

This universal tensile testing machines addresses the needs of standardized and routine testing, providing the user high quality at the most affordable price. The single column testing systems are suited for tension and/or compression applications where tests are less than 5 kN and lab space is limited. They are typically used for quality control and production testing.

Typical specimens: plastics, fine wire, fibers and threads, biomaterials, thin films, adhesives, foam, packaging, paper products, consumer products

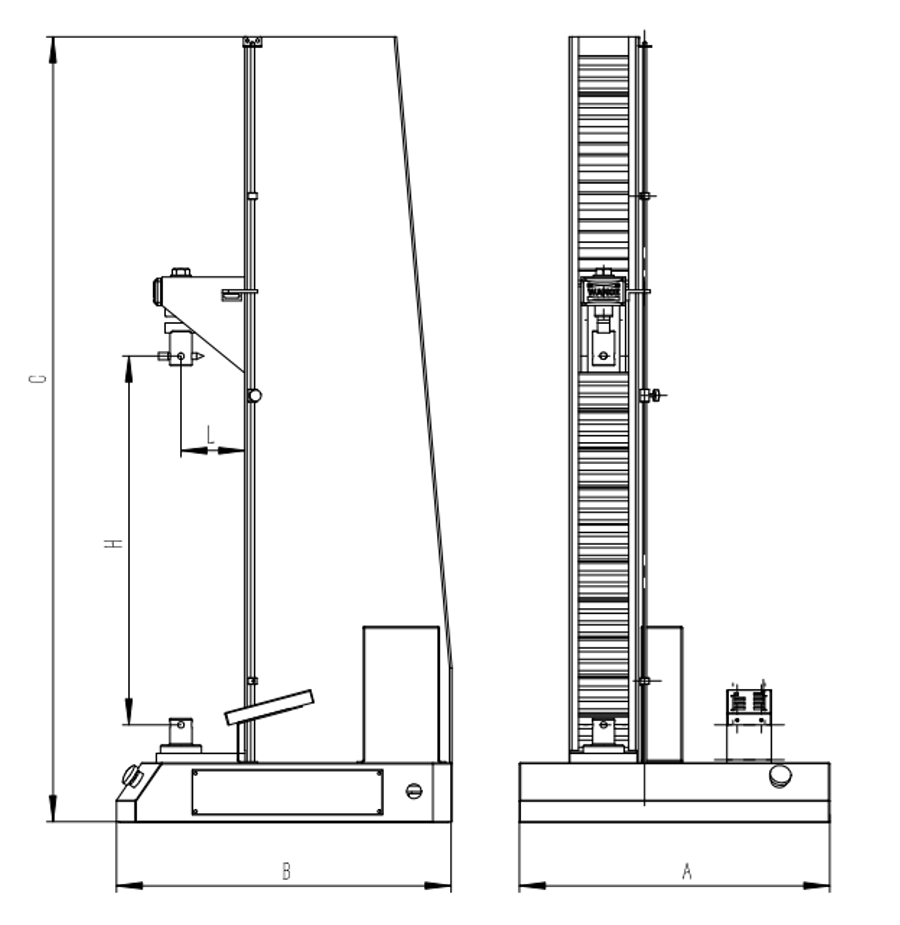

Machine dimension:

Frame type | Width x Depth x Height A x B x C (mm) | Crosshead travel H (mm) | Front opening space L (mm) | Adapter (mm) | Pin (mm) |

Standard | 560x550x1660 | 1000 | 100 | Ф20 | Ф10 |

Model | TSE503, TSE203, TSE103, TSE502, TSE202, TSE102 |

Type | Type A, single column |

Capacity | 5kN, 2kN, 1kN, 0.5kN, 0.2kN, 0.1kN |

Accuracy | 0.5% |

Force range | 0.4% ~ 100%FS |

Force accuracy | ±0.5% of reading |

Force resolution | 1/500000FS |

Position accuracy | ±0.5% of reading |

Position resolution (μm) | 0.06 |

Crosshead speed (mm/min) | 0.005 ~ 500 |

Crosshead speed accuracy | ±0.5% of set speed |

Crosshead travel (without grip) (mm) | 1000 |

Distance from loading center to dust cover (mm) | 100 |

Dimension (mm) (w x d x h) | 560x550x1660 |

Power requirement | Single-phase, 220±10% VAC, 50/60Hz, 500W |

Weight (kg) | About 100 |

Dear customers, please send your comments and suggestions to us via the following form. We will contact you as soon as possible.

Scan and follow us

Copyright @Shenzhen Wance Testing Machine Co., Ltd.

All Rights Reserved Design by:zuoan.com.cn