+86 755 23057280

English

STRONGER

Optimization design of crosshead and columns by finite element analysis; a large number of preload designs and assembly processes are used to optimize the various fits of ball screws and nuts, bearings and sensors, so as to reduce mechanical fit clearances, greatly improve the overall stiffness of the machine, and provide a guarantee for the test accuracy in the research of cutting-edge materials such as metals, rubbers, plastics and films. Single column frame is assembled with extra linear guide and dual-column frame is assembled with extra guidance columns, increasing the stiffness more.

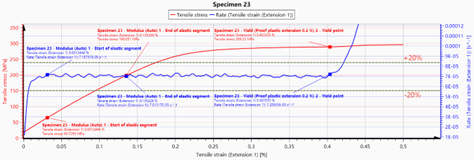

· Ensure higher measurement accuracy, to determine elastic modulus, yield strength and tensile strength.

· Offer higher test stability, repeatability and reliability, which is the most important in the field of aerospace and research institutes.

· More versatile to test different materials, from soft rubber and plastic, to higher strength alloys and composites.

· Small vibration after specimen fracture, more durable to use.

FASTER

The main machine transmission system of the ETM new-generation electronic universal testing machine adopts a servo direct-drive architecture, replacing traditional speed reducer transmission with a high-rigidity synchronous belt transmission system to achieve comprehensive performance improvements. Key advantages include:

Performance Enhancement

· Higher Test Speed & No-Load Return Speed: Significantly shortens test cycle time and improves efficiency.

· Faster Acceleration Response: Enables rapid adjustment of test conditions for faster testing requirements.

· Enhanced Operational Stability & Reliability: Reduces mechanical vibration and backlash, ensuring consistent and accurate measurement data.

Precision Improvement

· The direct-drive structure eliminates energy loss and mechanical clearance caused by traditional reducers, thereby improving test precision and providing more reliable data support for material research (e.g., metals, composites, polymers).

· Energy Efficiency Optimization

· Lower Energy Consumption: The servo direct-drive system operates with higher energy efficiency, reducing power loss compared to traditional transmission modes.

· High-Efficiency & Energy-Saving Technology: Ideal for high-strength, high-frequency test scenarios (e.g., quality control in manufacturing, material fatigue testing), balancing performance and sustainability.

Technical Support for Cutting-Edge Applications

· The optimized transmission system meets the testing needs of advanced materials (e.g., ultra-high-strength alloys, flexible electronics, biodegradable plastics), providing a robust technical foundation for R&D and quality assurance in emerging industries.

· This upgrade not only enhances the machine’s core performance but also aligns with global trends toward energy efficiency and intelligent manufacturing, making it a versatile solution for modern material testing laboratories.

SAFER

· Collision mitigation function offers sensitive detection of force change. It will stop automatically when force changing reaches the preset threshold. This function will reduce damages to load cell and specimens.

· Optional full-closed transparent shield with interlock function provides all-around protection for operators.

· Software can set the overload limit to prevent damage to load cell.

· Mechanical limit switch offers more protection.

SMARTER

Four primary colors that comply with the IEC 60073 standard allow visual interaction of the machine status by identifying different colors and modes.

SIMPLER

TestPilot Universal test software with easy-to-understand icon makes it easier to train operators and configure test process, mostly improving test efficiency while minimizing costly errors.

· Quick test is available to start a test with simple crosshead control and simple calculation of maximum force and displacement.

· Preset testing methods: TestPilot includes a large quantity of pre-configured methods for some of the most commonly used ASTM, ISO and EN standards. Methods are specifically designed for different shape of specimens with different test accessories.

· Intuitive design of testing process: with step-by-step instructions, users can easily design a complete testing process with error-free.

· Integrated touch screen PC with intuitive test software facilitates test operation.

EASIER

Controller is easy to pull out for maintenance, greatly improving service efficiency. Improved cover design is easier to repair and maintain.

Frame

· Robust guidance columns with self-lubrication increase lateral stiffness and ensure linear crosshead travel. This results in accurate crosshead alignment thus reducing variability in measurement data and control.

· Synchronous belt features high-speed, low vibration, world-class and maintenance-free.

· Photoelectrical encoder built in servo motor system is for position measurement of crosshead.

Load cell

· High- precision load cell offers high stiffness, high stability and high linearity.

· Over-load protection, lateral loading protection.

· Bi-direction allows tension and compression test.

· Self-recognition (TEDS) function.

· Regular self-calibration.

· Working temperature: -55℃~90℃.

Controller

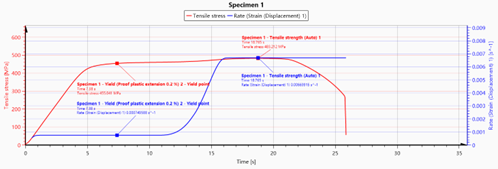

· Excellent control performance: The improved closed-loop control algorithm is matched with the upgraded transmission system, which shortens the system response time and enables the equipment to provide excellent control performance under various working conditions. Precise speed control and a reasonable smooth switching strategy fully meet the requirements of tests on metals at normal temperature and high temperature.

High temperature tensile strain speed: 0.00007/s

Tensile test smooth switch between different control

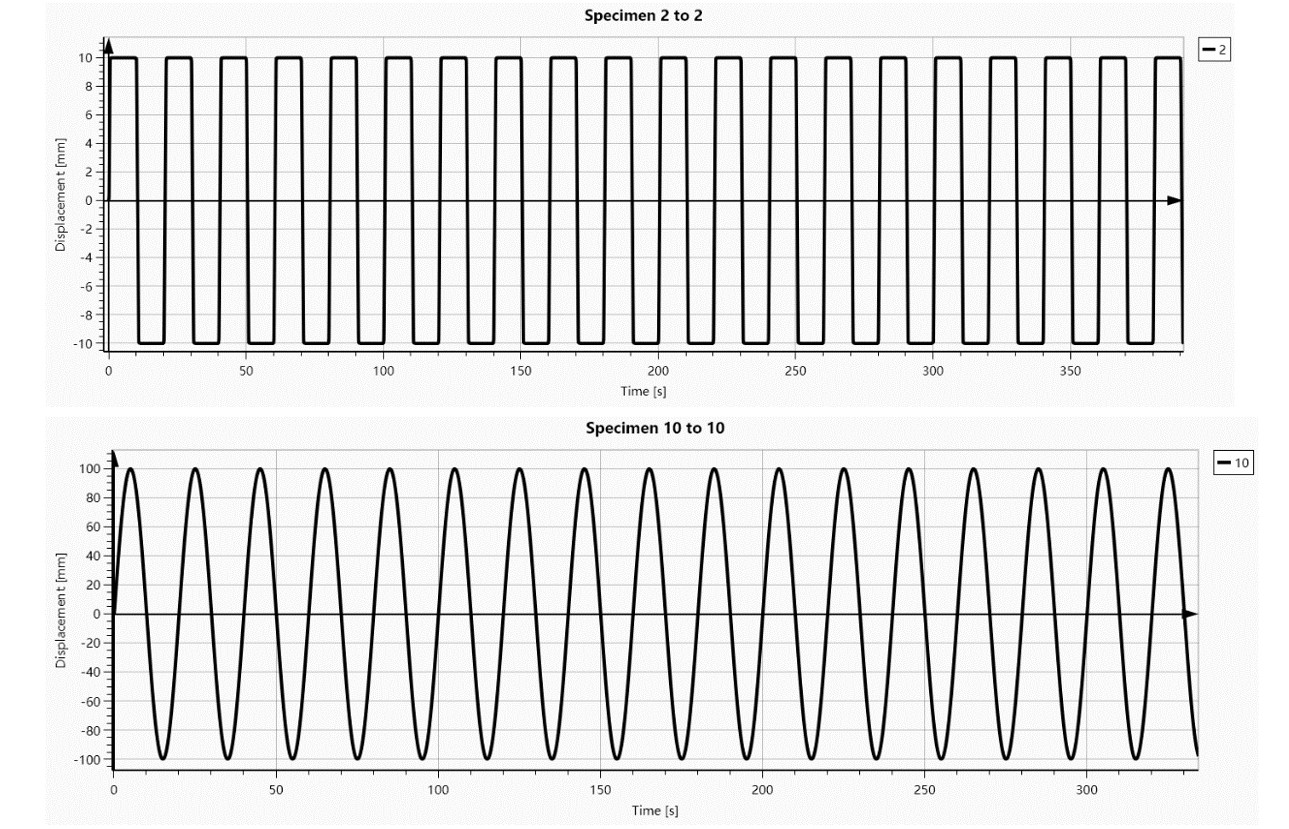

· Waveform generation: able to generate waveform control, like sine waves and trapezoidal waves.

· TEDS function: transducer self-identification system, interface features can be set online by software, system structure is more reasonable;

· Analogue signal output: optional BNC outputs enable output any two transducer signals to other data acquisition system, ±10V voltage.

· Better safety: With the integrated collision protection function, the system closely monitors the abnormal changes in the force value. When an abnormality occurs, it will immediately stop the movement of the crosshead, which can greatly reduce the damage to the equipment and samples caused by wrong operations and incorrect settings.

· Ethernet/USB communication is supported, and the transmission rate is greatly increased to support higher sampling frequency. Ethernet interface adopts special high-performance Ethernet interface chip and hardware logic gate circuit to realize complex TCP/IP protocol cluster, which has significant advantages such as high reliability and good security;

· Four-layer PCB layout, anti-resistance, high reliability;

· Connector with locking function, strong and durable, not easy to fall off, the interface layout is neat and reasonable, easy to plug and unplug;

· 6-channel 24-bit AD measurement channel;

· Up to 1200Hz sampling frequency;

· Up to 1200Hz closed loop control frequency;

· 20-bit resolution digital input;

· 3-channel high-speed digital acquisition, which is used to collect orthogonal pulse signals such as photoelectric encoder and grating ruler, with the highest signal acquisition frequency up to 4MHZ;

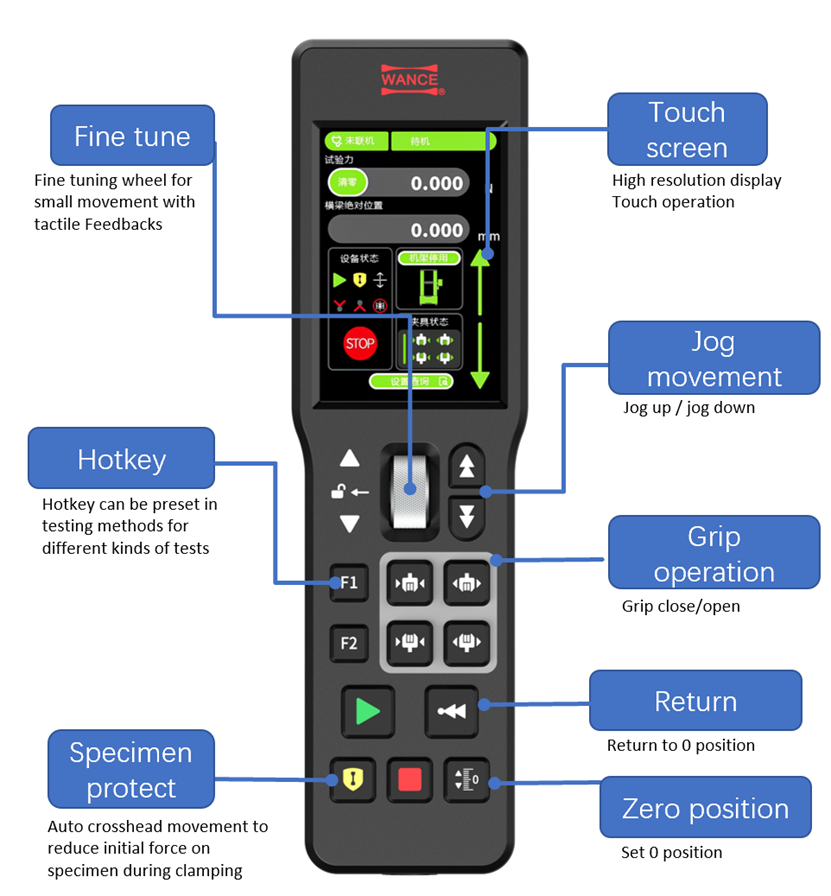

Handset

The HandsetV3.0 handset is equipped with a 3.5-inch touch color screen and silicone buttons, featuring a delicate texture and easy to hold. With the function of fine-tuning the crosshead through the wheel, it can accurately achieve precise adjustment of small displacements and small force values. At the same time, it supports dual-mode communication, namely direct connection to the controller and communication with PC software, providing flexible and efficient compatibility. The magnetic handset makes it more convenient to store and attach to the bracket, taking into account both operation efficiency and space management, and fully meeting the needs of high-precision testing scenarios.

· 3.5” touch screen can display force, position and status

· Fine tuning with wheel

· Grip open and close control

· Specimen protection

· Test on / stop

· Crosshead up / down

· Return to initial position

· Remember initial position

Optional operation panel

With advanced ergonomic design, the entire ETM system is equipped with high-definition integrated touch computers as optional. The TestPilot V3.0 testing machine software independently developed by us is built-in. The control panel is highly integrated with the testing system, and the operation radius is compressed to a golden working circle of 0.5 meters. Operators do not need to move back and forth between the computer and the testing system, which saves time and improves work efficiency.

Optional workbench

Ergonomic design workbench facilitates machine operation and accessories storage.

Standard size (LxDxH): 793x658x675mm

Optional protection shield

This protection system adopts an integrated fully enclosed structural design, equipped with an aluminum alloy reinforced frame and a 5mm impact-resistant PC global observation window, strictly following the mechanical safety standards. The protective cover is equipped with a safety door switch lock, and the corresponding access control strategy is configured in the software. It can effectively provide all-round occupational protection for operators.

Optional pneumatic control modular

Modular design which integrates air pressure regulation, flow rate management and fixture control, saves space and makes lab more beautify and tidier. This design prevents excessive pressure on specimen, or slippage during tensile test, greatly improve testing accuracy and stability.

TestPilot Universal software

Newly designed test software with simple layout: Simple and clear, with a reasonable arrangement of functions, a well-organized structure, and a unified style. It supports both horizontal and vertical screen display, and the software resolution adapts automatically according to the computer screen. The software has a large pre-installed library of test methods, including the most commonly used standards such as GB/T, ASTM, ISO and EN. These methods are packaged in different test modules according to specific test applications, meeting the test requirements of various industries. Users can customize test standards and plans. The modular accessory management system organically combines the display and actions of accessory information with the test process. It can be connected to a variety of accessories, such as video extensometers, temperature controllers, dial indicators, fully automatic extensometers, high and low temperature chambers, pneumatic controllers, strain gauges, etc.

· Interface Design: Using a simple and flat interface design style, it conforms to modern software design concepts, creating a simple, grand visual effect and a sense of high-end quality for users. At the same time, the font display is optimized, significantly improving the user's reading experience.

· Layout and Touch Optimization: It supports the adaptive horizontal and vertical screen layouts and is compatible with a variety of display devices. For touch input, a numeric keypad is added to optimize the touch input experience and ensure operational convenience.

· Demonstration Mode: After the test is completed, it supports generating simulation test files for offline operation of simulation tests.

· Recalculation: After the test is over, the test parameters can be modified and the results can be recalculated.

· Test Standards: The software has a large number of built-in test methods and can meet the requirements of common standards such as GB/T standards, ASTM standards, ISO standards and EN standards.

· Method list: The test methods and test processes are intuitively displayed, and classification and keyword filtering functions are provided to help users quickly locate the required content.

· Quick Test Method: A minimalist configuration process has been designed for users, enabling them to complete tensile and compression tests with the fewest steps.

· Data Export: After the test is completed, it supports one-click export of raw data to ensure the convenience of data acquisition.

· Test Progress Visualization: each test step is highlighted during executing, and total running time, control mode, control rate, and the number of cycles in real time, allowing users to have a clear understanding of the test progress.

· Test Graph: The graph supports multiple interaction methods such as keyboard, mouse and touch, and operations such as positioning, zooming, and panning of the global or single coordinate axis can be performed. It supports adding auxiliary lines, dual Y-axes, logarithmic coordinate axes, and allows users to customize the default boundaries of the coordinate axes, fully meeting users' complex needs for curve analysis and comparison.

· Function Key Customization: According to the requirements of the current test method, it supports customizing the function key panel to help users control the test efficiently.

· Test Log Recording: Key node step parameter information, event information, action information, and abnormal alarm information during the test process are recorded throughout the process, providing a basis for users to view the test process and analyze the causes of abnormalities.

· Pre-test Parameter Verification: Through a strict parameter rationality verification mechanism, abnormal states are eliminated before the test starts, avoiding test failures or sample waste caused by improper parameter settings.

· Sample Protection Mechanism: The force is automatically released during the clamping process to prevent sample damage. At the same time, users are allowed to customize sample protection parameters to meet different test requirements.

· Real-time Data Display: It supports the real-time display of all measurement channels and calculation results, with a maximum of 12 channels that can be added. Users can freely adjust the layout, switch units, set decimal places and refresh intervals. The currently controlled channel is highlighted, and the time channel supports display in the format of "hour:minute:second", fully meeting customers' customized requirements for channel sampling display.

· Multifunctional Operation Panel: Integrates all manual control functions of the controller and accessories, providing users with a quick operation interface for the equipment and accessories.

· Basic Templates: Four standard templates for simplifying the test process configuration are provided to help new users quickly get started and complete the test method configuration. Experienced users can use the expert template for flexible configuration to achieve customized design of complex test control processes.

· Unit System: The international unit system and the imperial unit system are built-in, and users are supported to customize units to meet special test requirements. Users can switch the unit system of the method and the test with one click to ensure operational convenience.

· Expression Generator: It supports constructing custom functions using a set of variables in the method, which can be used to detect test events, define user calculations, virtual measurements, or calculation domains, helping users create complex calculation logic efficiently and intuitively.

· Measurement Function: It supports using all accessory channels as physical measurement channels, collecting data in real time during the test and drawing curves. Virtual measurements can be defined through expressions, and the expression variables can be other measured values or user input parameters to meet the needs of complex measurement channels. For measurements that support rate units, users can add associated rate measurements as needed.

· Calculation Function: Multiple commonly used algorithms are preset, and relevant parameter configurations are opened to help users quickly configure result calculations.

· Rounding Function: It supports configuring multiple rounding rules, and users can directly select them in the result settings to ensure the standardization of data processing.

· Test Control: Diverse step modes such as absolute ramp, relative ramp, hold, zeroing, and waveforms (sine wave, square wave, triangular wave) are provided, and actions such as step switching triggered by events are supported. Users can also set acquisition strategies for different steps to meet advanced customization requirements.

· Voice Broadcasting Function: Voice broadcasting can be executed before the test, when removing the extensometer, and at the end of the test. The broadcasting content can be customized to enhance the user's operation experience.

· Accessory Connection: It can be connected to a variety of accessories, such as dial indicators, fully automatic extensometers, video extensometers, high and low temperature chambers, etc.

· Accessory Action Control: It supports interspersing accessory actions at various stages of the test process to help users flexibly control accessory actions.

· Data Acquisition Strategy: For all measurement channels, users can customize the data acquisition interval to avoid missing the sudden change parts of the measurement data due to a single rule.

· Automatic Fixture Pressure Setting: It supports the automatic setting function of the fixture pressure. After the fixture exceeds the threshold value, the clamping percentage is synchronously increased according to the change of the maximum force to prevent the sample from slipping during the test.

· Test Report: It supports customization functions such as text watermark marking, and at the same time supports saving the report template in a file format, making it convenient for users to configure and reuse.

· Multi-language Switching: It supports one-click language switching without restarting the software, ensuring that users have a smooth operation experience in a multi-language environment.

· Data Analysis: Cross-scheme and cross-test data comparison: It supports comparison and analysis of data from different test schemes and different tests, helping users deeply explore the value of the data.

· Maintenance Reminder: When the software is started, it automatically reminds users according to the preset maintenance rules, helping users to carry out equipment maintenance in a timely manner and improving the safety and service life of the equipment.

· Permission Configuration Management: It supports permission allocation according to user roles, effectively preventing accidental modification of test methods and system configurations, and ensuring the stability of system operation.

· Safety Performance: All-round protection measures: It has a powerful safety protection mechanism, covering safety prompts for test method loading, global measurement limit protection, preloading over-travel and overtime protection, sensor range protection, test suspension/termination after the protective door is opened, sample protection over-travel protection, etc., providing all-round protection for the safety of the test process.

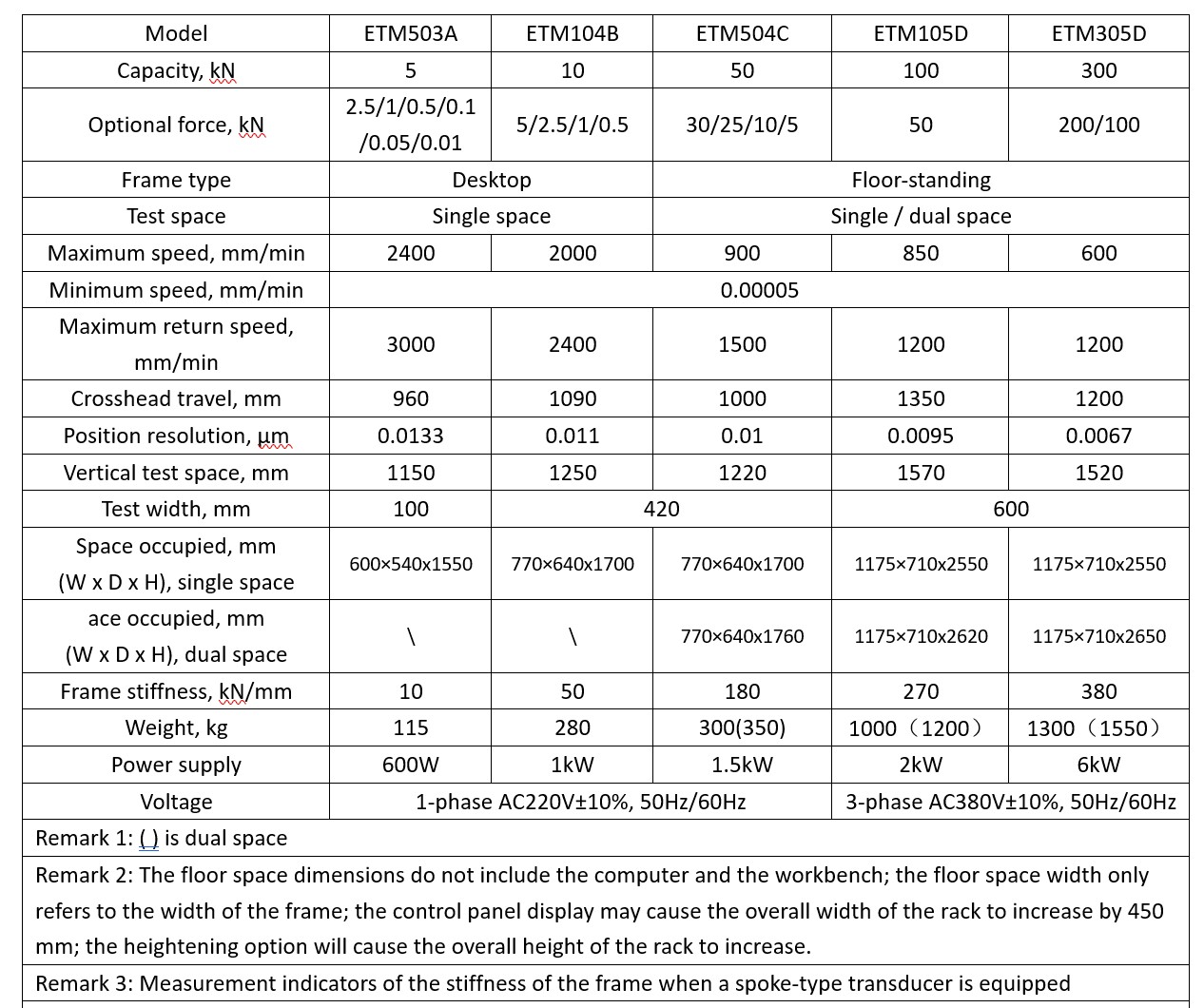

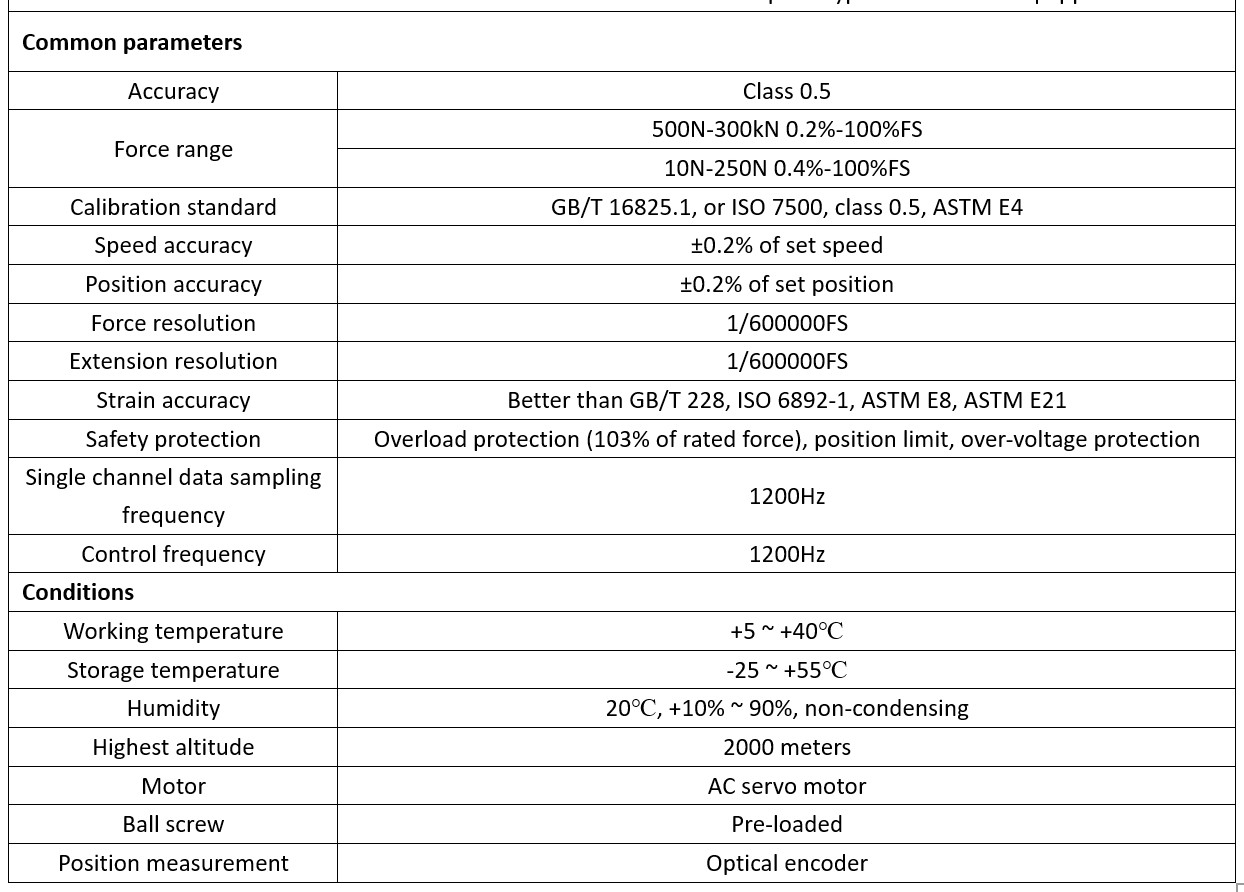

Parameters

Dear customers, please send your comments and suggestions to us via the following form. We will contact you as soon as possible.