+86 755 23057280

English

+86 755 23057280

English

ASTM D7264/D7264M-21

Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials

Significance and Use

5.1 This test method determines the flexural properties (including strength, stiffness, and load/deflection behavior) of polymer matrix composite materials under the conditions defined. Procedure A is used for three-point loading and Procedure B is used for four-point loading. This test method was developed for optimum use with continuous-fiber-reinforced polymer matrix composites and differs in several respects from other flexure methods, including the use of a standard span-to-thickness ratio of 32:1 versus the 16:1 ratio used by Test Methods D790 (a plastics-focused method covering three-point flexure) and D6272 (a plastics-focused method covering four-point flexure).

5.2 This test method is intended to interrogate long-beam strength in contrast to the short-beam strength evaluated by Test Method D2344/D2344M.

5.3 Flexural properties determined by these procedures can be used for quality control and specification purposes, and may find design applications.

5.4 These procedures can be useful in the evaluation of multiple environmental conditions to determine which are design drivers and may require further testing.

5.5 These procedures may also be used to determine flexural properties of structures.

Scope

1.1 This test method determines the flexural stiffness and strength properties of polymer matrix composites.

1.1.1 Procedure A—A three-point loading system utilizing center loading on a simply supported beam.

1.1.2 Procedure B—A four-point loading system utilizing two load points equally spaced from their adjacent support points, with a distance between load points of one-half of the support span.

NOTE 1: Unlike Test Method D6272, which allows loading at both one-third and one-half of the support span, in order to standardize geometry and simplify calculations, this standard permits loading at only one-half the support span.

1.2 For comparison purposes, tests may be conducted according to either test procedure, provided that the same procedure is used for all tests, since the two procedures generally give slightly different property values.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

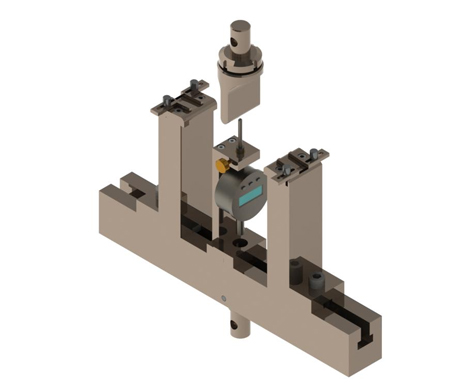

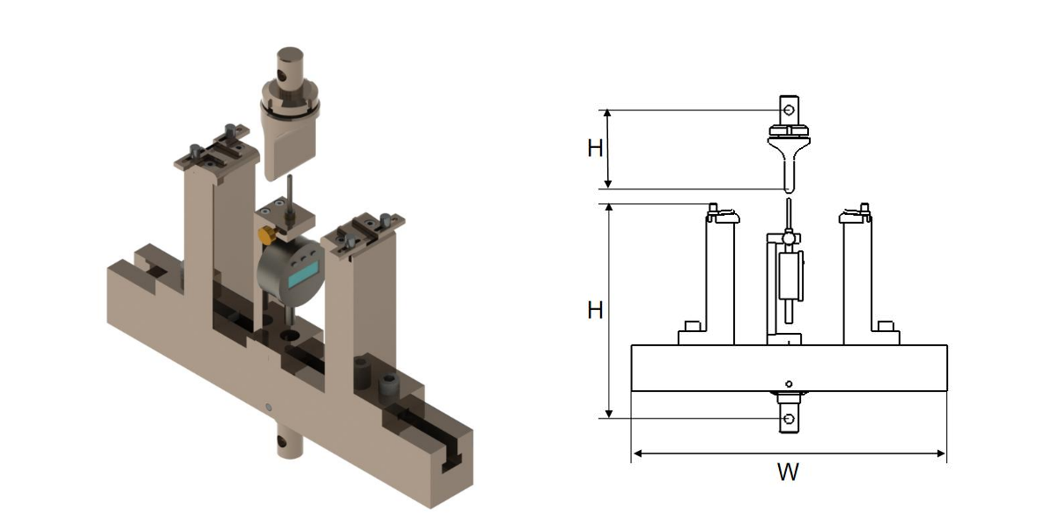

Application | For Flexural Properties Test of Polymer Matrix Composite Materials |

Maximum force | 10kN |

Connection | |

Upper grip | Φ10 mm pin |

Lower grip | Φ10 mm pin |

Height | |

Upper grip (A) | 90 mm |

Lower grip (B) | 232 mm |

Total width (C) | 340 mm |

Working temperature | 0℃~40℃ |

Test standards | ASTM D7264, ISO 14125, GB/T 9341 |

Upper grip weight | 0.5 kg |

Lower grip weight | 9.2 kg |

Bending nose | Ф10mm, exchangeable |

Support roller | Ф4, Ф10mm, exchangeable |

Specimen width | 45 mm |

Maximum span | 10~200mm, adjustable |

Dear customers, please send your comments and suggestions to us via the following form. We will contact you as soon as possible.

Scan and follow us

Copyright @Shenzhen Wance Testing Machine Co., Ltd.

All Rights Reserved Design by:zuoan.com.cn